"Every mouthpiece carries the soul of its creators, a reflection of their artistry, a testament to their passion, and a legacy that echoes through every note."

Bringing Icons into the Modern Era

For over a century, Meyer and Otto Link defined the sound of saxophone.

Today, JJ Babbitt and Theo Wanne have rebuilt the process required to deliver those designs consistently, without sacrificing their character.

How Iconic Mouthpieces Are Built Today

For over a century, Meyer, Otto Link, and J&D Hite mouthpieces have shaped the sound of saxophone and clarinet. These designs didn’t just influence generations of players, they became the reference point the entire industry responded to.

What changed over time was not the passion players had for these designs; it was their expectations. In a more technologically advanced era, players began expecting a level of precision, consistency, and repeatability that legacy processes could not always deliver as reliably as the designs deserved.

Today, through our partnership with Theo Wanne Mouthpieces, we’ve blended the best of modern technology and process control with legacy material processing and hand-finishing to create a unique, proprietary workflow that meets and exceeds today’s expectations.

This is not a return to the past, and it’s not a rejection of it. It’s an evolution that combines proprietary materials, modern precision, and human discernment to deliver iconic mouthpieces with the reliability players have been asking for.

A Different Kind of Craft

For years, mouthpiece making forced a false choice: precision or character. Automation promised repeatability. Handwork promised feel. Too often, players had to choose between consistency and a lottery for the sound they loved.

That tradeoff no longer exists.

Meyer, Otto Link, and J&D Hite mouthpieces are now crafted through hybrid manufacturing that brings together the strengths of two workshops into one unified standard. Certain stages happen at JJ Babbitt. Certain stages happen with our partner, Theo Wanne Mouthpieces. The work then returns to JJ Babbitt for final evaluation and finishing.

This is not CNC for the sake of automation. It is precision used intentionally, so craftsmanship can matter where it matters most.

Where Precision and Artistry Meet

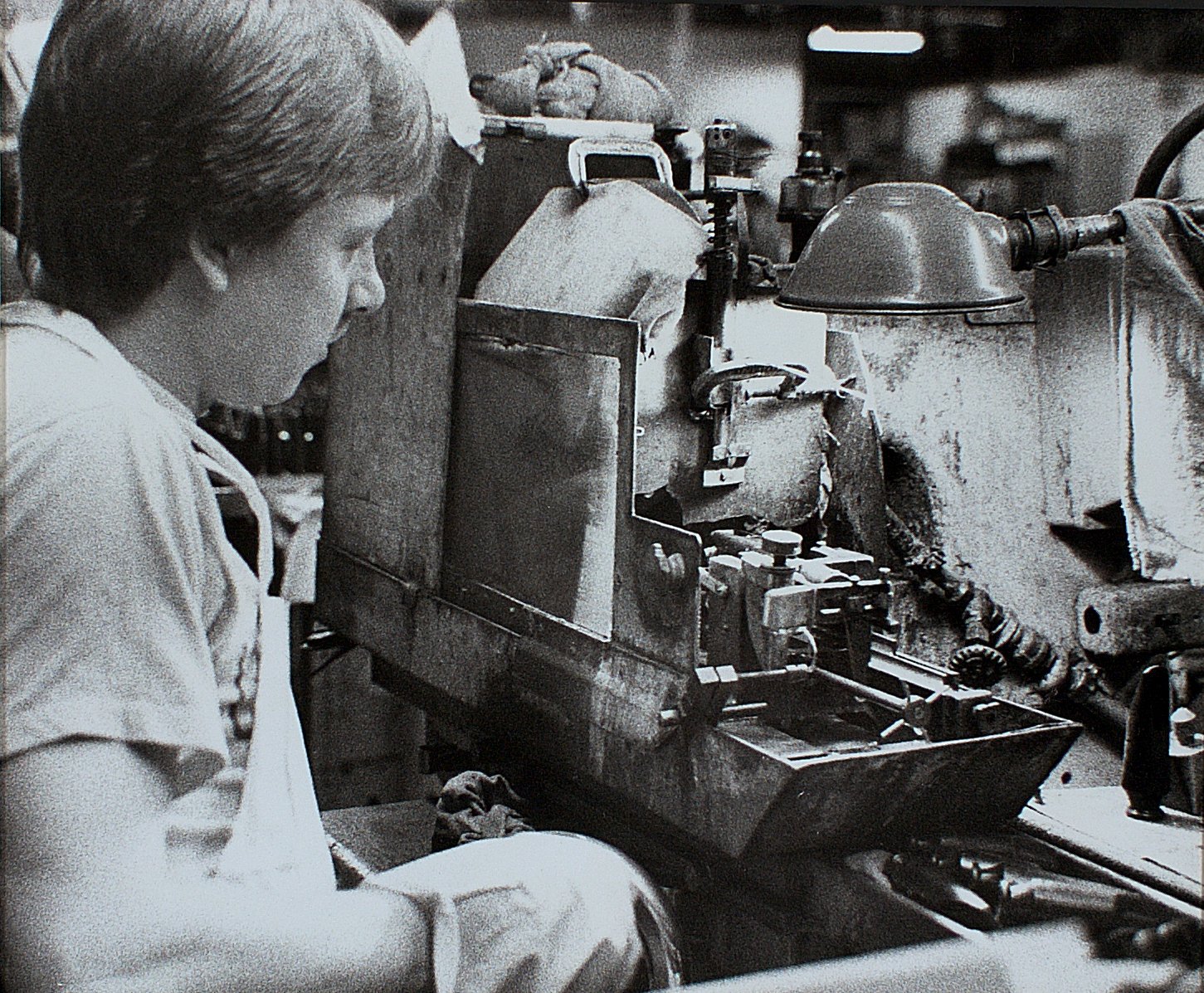

Modern CNC machining, guided by the deep mouthpiece expertise of Theo Wanne, establishes accuracy, repeatability, and control at the foundation of each mouthpiece. It reflects decades of design knowledge, refacing experience, and intentional decision-making applied through advanced tooling, ensuring each mouthpiece always matches the original intended design.

From there, the process returns to JJ Babbitt, where final finishing, refinement, and quality control take place. This stage draws on generations of hands-on experience and techniques now guided by Theo Wanne’s decades of refacing expertise, to shape how the mouthpiece ultimately feels and responds. When geometry is more tightly controlled from the start, human expertise can focus on refinement rather than correction. That’s where craftsmanship matters most.

This is not a division between machines and people. It’s a collaboration between skilled makers, using the right tools at the right moments to serve the sound.

Technology sets the standard. Human ingenuity guides every step.

What This Means

This process isn’t just about making mouthpieces identical. It’s about making the iconic, golden-age Meyer and Otto Link designs attainable.

Expression comes from the player. Consistency ensures the mouthpiece doesn’t get in the way. When unnecessary variability is removed, players spend less time compensating and more time making music.

The goal is simple: If you pick up a Meyer or Otto Link mouthpiece today, it should deliver the design, sound, and feel you expect, reliably.

That’s what this new process exists to do.

Hard Rubber Mouthpieces

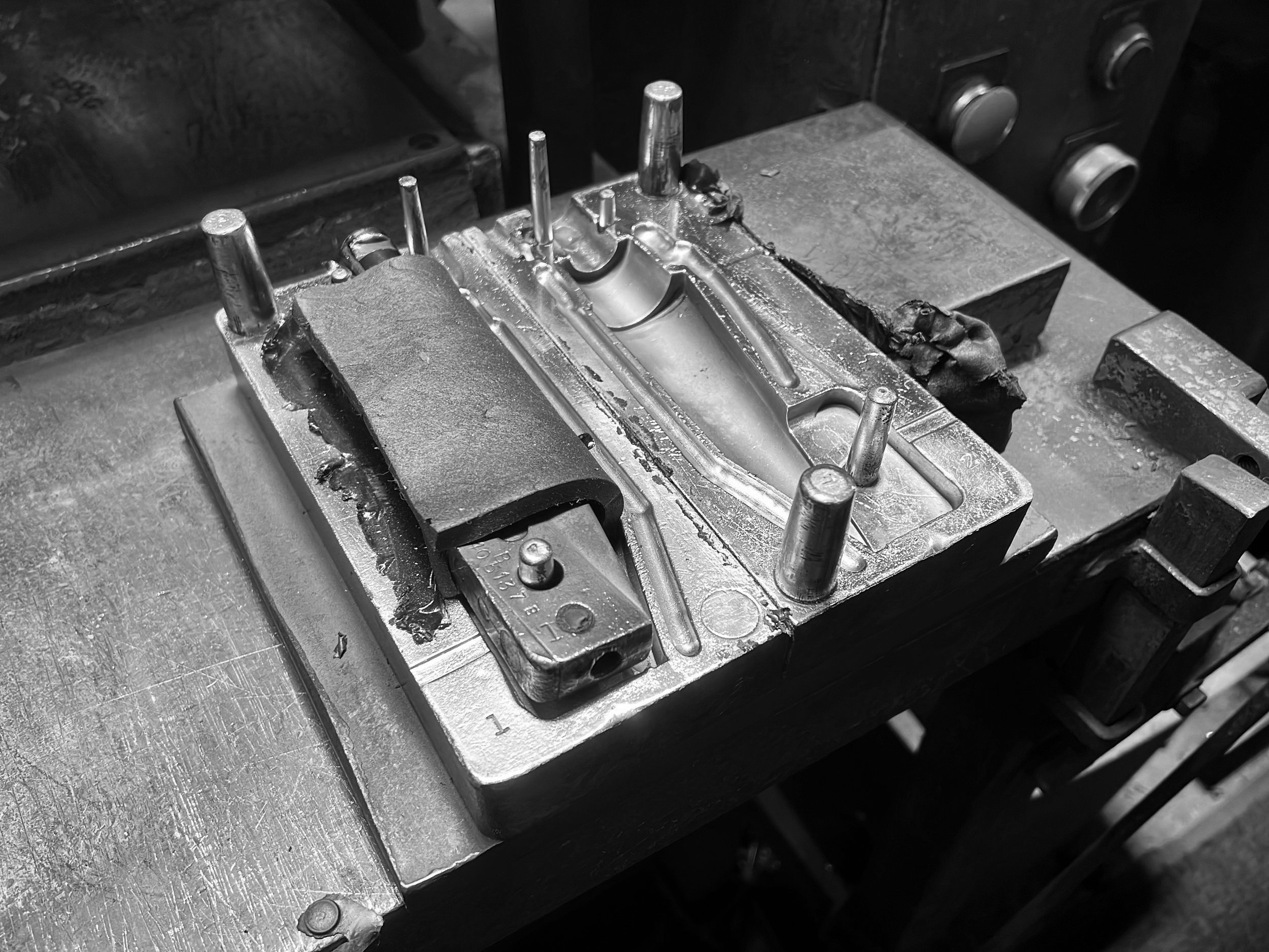

Meyer and Otto Link hard rubber mouthpieces begin with the raw material.

JJ Babbitt uses a proprietary rubber formulation and processing method developed specifically for these designs. The rubber is mixed, molded, and vulcanized in-house, establishing the density, resonance, and tonal core that define the Meyer and Otto Link sound.

These mouthpieces do not begin as pre-vulcanized bar stock or generic extruded rod. The way the rubber itself is created is a meaningful contributor to how these mouthpieces sound and respond, and it is one of the reasons their tonal character cannot be fully replicated by copying dimensions alone.

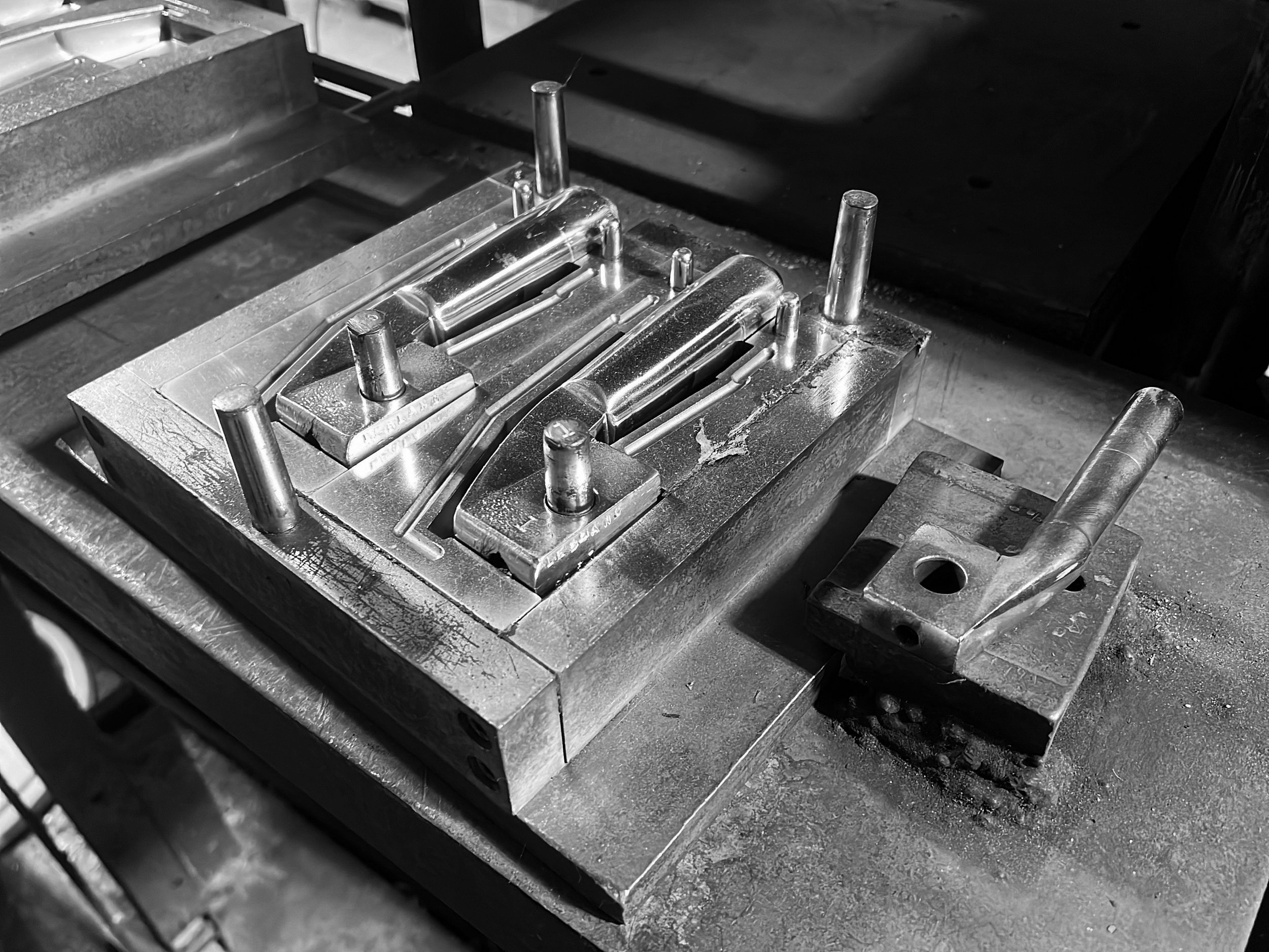

That material is then formed using the original molds and cores developed for Meyer and Otto Link. These are not reinterpretations or approximations. They are the same foundational tooling that has shaped these mouthpieces for generations, ensuring continuity in feel, response, and tonal identity.

Once that foundation is established, modern CNC machining is applied to bring accuracy, repeatability, and control to the internal geometry. Each mouthpiece then returns to JJ Babbitt for final hand finishing, evaluation, and refinement.

The result is not a choice between old and new. It is a unified process that preserves the tonal identity players expect while delivering the consistency they have long wanted to trust.

Metal Mouthpieces

Otto Link metal mouthpieces begin with structure.

Today, Otto Link metal mouthpieces are produced from a single piece of brass rather than two separate halves joined together. This approach eliminates an unnecessary variable in the manufacturing process and allows for tighter control over internal geometry, dimensional accuracy, and repeatability.

This evolution was not driven by aesthetics or efficiency alone. Extensive research, testing, and validation were conducted to understand whether differences in construction methods meaningfully affect tone or playability. The conclusion was clear: while metallurgical properties can differ subtly, those differences are not significant enough for players to experience a meaningful change in sound or response.

What does change is reliability.

By machining from a single piece of brass, modern CNC processes establish the core architecture of the mouthpiece with exceptional accuracy and consistency. Chamber shape, baffle geometry, and critical dimensions are executed far closer to design intent from the very beginning.

From there, each mouthpiece returns to JJ Babbitt for final hand finishing, evaluation, and refinement. This stage focuses on feel, response, and balance, applying informed human judgment to ensure the mouthpiece plays the way it was designed to play.

The result is not a different Otto Link sound.

It is the same tonal intent delivered with far greater confidence.

Players no longer have to search for “the good one.”

They can trust that the Otto Link they pick up reflects the design, character, and performance the name has always promised.

A Process Finally Worthy of the Sound

The mouthpieces that defined the sound of saxophone deserve a process that can honor them properly.

This is not just marketing.

This is the work required to do iconic designs justice.

Welcome to the new era of Meyer and Otto Link.

-

CNC machining is used to establish accuracy and repeatability where precision matters most. It creates a reliable foundation so that final finishing decisions are informed, not corrective.

CNC doesn’t replace judgment. It removes unnecessary variability so judgment can matter more.

-

No. It means handwork now happens at the right stage of the process.

When early geometry is controlled, final finishing becomes refinement rather than correction. That’s where skilled hands are most valuable.

-

No. It reduces surprises.

Expression comes from the player. Consistency ensures the mouthpiece delivers the design it claims to be, allowing players to explore their voice without fighting the equipment.